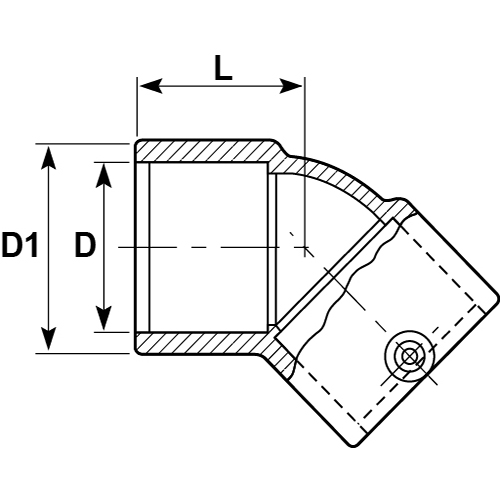

Electrofusion Elbows 45 Degree

39.5V Electrofusion System

The original Electrofusion was invented and patented in 1977 by Swiss company Von Roll (manufacturer of Steel Municipal Piping and Ski Lifts). The system was then called Rollmaplast. Many systems have developed since then with the basic initial concept of embedded resistance elements in each socket and coupler still being used today.

Advanced Piping Systems 39.5 Volt Electrofusion System has increased since our beginnings in 1990 to include the large sizes used in utility piping systems today.

Giant 1 Metre diameter couplers with dual heating zones mean that situations that previously required a mechanical joint can now be accomplished with a socket to give the ultimate leak proof fully fused system.

The question is often asked: "should we buttweld or electro-fuse?", we can help you with this, as both have their place and as the industry has matured there is increasing numbers of projects that utilise both buttwelding and electrofusion welding on the same pipeline.

Advanced Piping recognise this, and have a large range of buttfusion and electrofusion welding machines available for short and long-term hire.

Please note that Advanced Piping Systems' EF sockets and couplers are manufactured from Virgin PE100 resin and are compatible with any barcode reading, or manual programmable welding machine.

Please check the welding machines capacity first, however, as large EF sockets have a higher current/amp requirement. Advanced EF sockets are available in up to 1600mm.

EF Sockets can also weld a range pipe classes above & below their own rating pressure rating will be limited to the lessor. This means they can also be used as an SDR transition very effectively.

Advanced Piping Systems' EF sockets are available in:

- PN25 SDR 7.4 – 32mm – 400mm

- PN20 SDR9 - 450 - 630mm

- PN16 SDR11 20mm – 1200mm

- PN10 SDR17 from 355mm to 1600mm

Compliance

Articles

Expansion Management: Navigating HDPE Pipe Installations

HDPE piping has rapidly gained popularity among engineers and project managers seeking adaptable, flexible, and rust-resistant piping solutions. Whether for a temporary or permanent installation …

HDPE vs carbon steel vs stainless steel – which pipe is right for energy savings?

As budgets get tighter and the expectation to reduce costs continues to rise, all businesses are on the lookout for ways to save. While some …

How to best replace steel bends with wear resistant HDPE

Image: Highlighting the challenge of fitting a 3D bend, this photo shows a modified guardrail to accommodate it. Contrastingly, the 1.5D bend behind seamlessly fits …

A nickel in time saved nine for this international project

In 2022, an international mining company specialising in nickel and cobalt approached Advanced Piping Systems for assistance in a time-sensitive project related to their mine …