/Universal-Adaption-Joints-to-PECast-IronDuctile-IronSteelPVCACCopper-300x300.jpg)

/universal-adaption-joints-pe-cast-iron-ductile-ironsteel-pvc-ac-copper-butt-or-electrofusion-welding_dia.jpg)

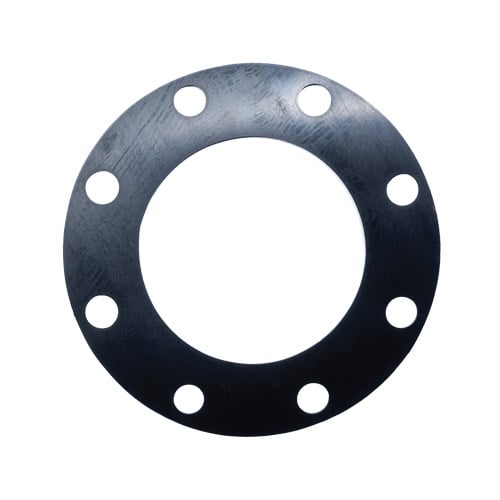

Universal Adaption Joints

Long Spigot Fittings

The Advanced Piping Systems universal adaption joint is a revolutionary fitting that is made especially for HDPE piping, and will permanently fix the adaption challenge of adapting and sealing poly pipes to other pipe materials.

Whether it be cutting into, or repairing, an old existing inground service, when the universal adaption joint is connected onto an existing pipe this coupling will never pop off as traditional Gibault bolted couplers are prone to do overtime.

This coupling can adapt to cast steel or ductile iron, asbestos or fibre cement pipe, copper, and PVC as well as another PE/HDPE piping.

This coupling has also been tested and approved on some of Australia’s biggest gas utilities for the very same reason – they do not come off and they do not leak.

The adaption end of the coupling has been designed with a significant depth of socket end as well as a good adaption range that can be taken up by the elastomeric sealing teeth. When the coupling slides all the way home and bolts are tightened to the required torque – detailed on every coupling e.g, 180mm coupling requires 80Nm on all 4 bolts – this joint is not coming off even under extreme loadings. The large bolting lugs act as locators for casting into concrete thrust blocking.

The Advanced Piping Systems universal adaption joints are rated to PN16 and all come with SDR11 long spigots for buttwelding or electrofusion welding, in sizes 90mm with 84-108mm and adaption range to 400mm with 354-384mm.

Compliance

Articles

Expansion Management: Navigating HDPE Pipe Installations

HDPE piping has rapidly gained popularity among engineers and project managers seeking adaptable, flexible, and rust-resistant piping solutions. Whether for a temporary or permanent installation …

HDPE vs carbon steel vs stainless steel – which pipe is right for energy savings?

As budgets get tighter and the expectation to reduce costs continues to rise, all businesses are on the lookout for ways to save. While some …

How to best replace steel bends with wear resistant HDPE

Image: Highlighting the challenge of fitting a 3D bend, this photo shows a modified guardrail to accommodate it. Contrastingly, the 1.5D bend behind seamlessly fits …

A nickel in time saved nine for this international project

In 2022, an international mining company specialising in nickel and cobalt approached Advanced Piping Systems for assistance in a time-sensitive project related to their mine …