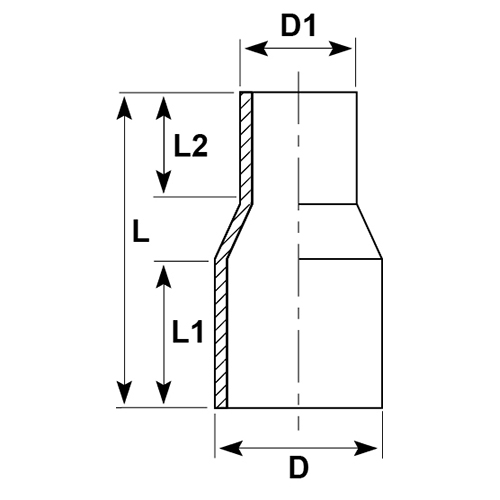

Concentric Reducers

Long Spigot Fittings

In a concentric reducer, the reduction is symmetrically central, and tapers evenly to the next size. buttweld concentric reducers are used to join pipe and fittings of different diameters to smaller pipe and fittings on the same common line axis, acting as hydraulic flow limiters. They provide an in-line conical transition between pressurised or non-pressurised pipe of different diameters. Our short spigot reducers have been designed with performance in mind, as well as enough spigot length to be clamped in the buttwelding machine flat clamps. They are also short enough to be used in a fast-end fittings chuck. Concentric reducers are the most utilised reduction in piping by ten to one. In isometrics and process piping designs this reducer fitting is also referred to as an enlarger, or expander, which means the flow direction will be reversed and come from the reduced side. This is commonly seen in pump discharges and process piping as it reduces back pressure, increases the flow and decreases the friction loss, especially over long pipe runs. Concentric reducers are generally considered best for purpose on vertical piping, unless obstacles or bracketry requirements need to be considered, and an eccentric reducer may be better suited. See the eccentric reducers section also available in long and short spigot. We can machine any reduction to your exact requirements and pressure rating when outside of our large concentric reducer range, which is available standardly in SDR7.4 PN25 from 25mm – 500mm, SDR11 PN16 20mm – 710mm and SDR17 PN10 63 – 1200mm.

Compliance

Articles

Beyond pipes – your mining questions answered

Mine projects are inherently unique, each presenting a set of challenges and specifications that require customised solutions. However, it’s often surprising how many of the …

Advanced Piping Systems’ precision HDPE spooling future-proofs iron ore mine

In 2022, Advanced Piping Systems supplied HDPE spooling and pipe to an A$100 million water management upgrade project at an iron ore mine in the …

Expansion Management: Navigating HDPE Pipe Installations

HDPE piping has rapidly gained popularity among engineers and project managers seeking adaptable, flexible, and rust-resistant piping solutions. Whether for a temporary or permanent installation …

HDPE vs carbon steel vs stainless steel – which pipe is right for energy savings?

As budgets get tighter and the expectation to reduce costs continues to rise, all businesses are on the lookout for ways to save. While some …