Stub Flanges

Buttweld Fittings

Flanged joints in pipelines are used to create a demountable joint for future disassembly to connect valves and vessels, either where strength in tension is required, or to join to other materials.

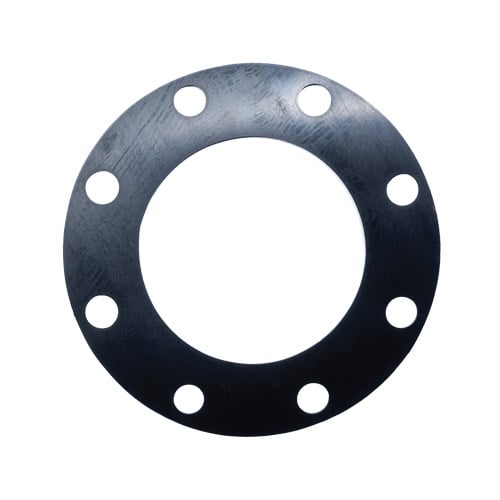

Advanced Piping Systems has a complete range of full-face flanges, accompanied by galvanised metal backing plates.

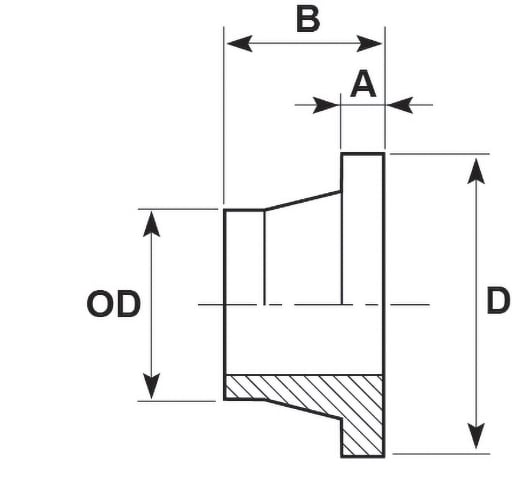

A range of Stub Flanges is also available, incorporating a backing ring.

These fittings are manufactured to Series 1, PN18 in accordance with Australian Standard AS/NZXS 1477. The system eliminates the traditional steel backing ring and replaces it with a sturdy structural flange plate making the joint lightweight and corrosion-resistant.

The flange is designed to connect sections of pipe or tube or to join the pipe or tube to an assembly such as a pressure vessel, valve or pump. Flanges are joined by bolting, while sealing is completed with the use of gaskets and other sealing methods and fixed to the piping system by welding or threading.

Compliance

/iso_9001_2015.jpg)

Articles

The Benefits of 90 Degree Elbow

Product Spotlight – 90 Degree Elbow in Long Spigot Fittings When it comes to optimising your piping system, the 90-degree elbow in long Spigot Fittings …

Debottlenecking Episode 3

Customised solutions For more challenging and unique situations, Advanced Piping Systems has the expertise to offer HDPE solutions for your specific needs. This was the …

Debottlenecking Episode 2

Gains on the inside Debottlenecking Episode 2 is now available! When making a pipe or fitting selection with performance in mind, deciding on the Inside …

Introducing Debottlenecking Video Series

Want to learn how to maximise efficiency in your next project? We’re excited to showcase the very first video of our Debottlenecking short video series. …